Flow Measurement

Tek-Trol has a wide product offering for measuring flow, covering many applications. Tek-Trol flow meters utilize six sensor technology types to measure flow: Coriolis, Ultrasonic Clamp-On, Vortex, Electromagnetic, Venturi, and Differential Pressure.

Product Categories

TEK-TROL - Tek-Cor 1100A Coriolis Flow Meter

TEK-TROL - Tek-Cor 1100A Coriolis Flow Meter

Designed to measure almost any fluid across any application, and does not require compensations for factors such as temperature and pressure, which impact volume and, in turn, impact the accuracy of measurement.

TEK-TROL - Tek-Flux 1400A Electromagnetic Flow Meter

TEK-TROL - Tek-Flux 1400A Electromagnetic Flow Meter

Measures the volumetric flow rates of any fluid which can adequately conduct electricity in closed pipelines. These instruments are highly accurate, reliable, and stable devices used in various high-pressure industrial processes. Available in a wide range of nominal pipe size diameters, from ½” to 28″ (0.04 ft to 2.33 ft) with IP65 protection.

TEK-TROL - Tek-Flux 1400B Insertion Electromagnetic Flow Meter

TEK-TROL - Tek-Flux 1400B Insertion Electromagnetic Flow Meter

For use in pipes from 4″ to 80″, adjustable depth (isolation valve included), no moving parts, and multiple signal outputs.

TEK-TROL - Tek-Flux 1400C Utility Electromagnetic Flow Meter

TEK-TROL - Tek-Flux 1400C Utility Electromagnetic Flow Meter

The Tek-Flux 1400C Utility Electromagnetic Flow Meter is available as Line or Battery powered and is NSF approved, allowing for use in potable (drinking) water applications.

TEK-TROL - Tek-Clamp 1200A-100EXP Explosion-Proof Ultrasonic Flow Meter

TEK-TROL - Tek-Clamp 1200A-100EXP Explosion-Proof Ultrasonic Flow Meter

Tek-Clamp 1200A-100EXP is a Class I Div ll Ultrasonic Flow Meter. Completely non-invasive ultrasonic flow

meter that uses an ultrasonic signal to measure the flow rates with the transit time method.

TEK-TROL - Tek-Vor 1300C Vortex Flow Meter

TEK-TROL - Tek-Vor 1300C Vortex Flow Meter

A versatile instrument that calculates the mass flow, volumetric flow rate, temperature, pressure, and density of any liquid, gas, or steam through a pipeline.

TEK-TROL - Tek-Thermal 1700B Thermal Mass Flow Meter

TEK-TROL - Tek-Thermal 1700B Thermal Mass Flow Meter

Compact design, measures mass flow and standard flow directly, accuracy ±0.5% FS, specially designed for use in air and nitrogen (N2) applications.

TEK-TROL - Tek-Flo 1300D Steam Quality Mass Flow Meter

TEK-TROL - Tek-Flo 1300D Steam Quality Mass Flow Meter

Utilizes two different flow meter technologies in combination; vortex and differential pressure. This allows for predicting the fluid density, volumetric flow rate, and mass flow rate without any fluid density information being required from an external source.

TEK-TROL - Tek-DP 1610D Series Integral Orifice Assemblies

TEK-TROL - Tek-DP 1610D Series Integral Orifice Assemblies

Used in combination with a multivariable transmitter to measure liquid, gas, or steam flow accurately.

TEK-TROL - Tek-DP 1610H Series Wafer Style Orifice Plate

TEK-TROL - Tek-DP 1610H Series Wafer Style Orifice Plate

Available in various line sizes (1/2″ to 24″) and meets ASME, AGA, and ISO Standards. The primary applications for the Tek-DP 1610H Wafer Style Orifice Plate are for gases, liquids, corrosive, and high-temperature fluids.

TEK-TROL - Tek-DP 1620A Series Cone Flow Meter

TEK-TROL - Tek-DP 1620A Series Cone Flow Meter

Ideal for liquid, steam, and gas media, used in rugged conditions where accuracy, low maintenance, and cost are important. With its DP built-in flow conditioning design, the Cone is great in tight-fit and retrofit installations where the long runs of straight pipe required by Orifice Plates, Venturi Tubes, and other technologies are impractical or unavailable.

TEK-TROL - Tek-DP 1640A Series Venturi Flow Meter

TEK-TROL - Tek-DP 1640A Series Venturi Flow Meter

Designed to measure almost any fluid across any application, and does not require compensations for factors such as temperature and pressure, which impact volume and, in turn, impact the accuracy of measurement.

TEK-TROL - Tek-DP 1650A DProbar Multiport Self-Averaging Flow Meter

TEK-TROL - Tek-DP 1650A DProbar Multiport Self-Averaging Flow Meter

A primary flow meter for measuring gas, liquid, and vapors flowing in the pipelines and ducts based on principles of differential pressure measurement (DP). Suitable for a wide range of pipe sizes. Allows insertion into pressurized pipes (Via a full port Valve and hot tap).

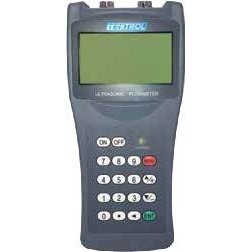

TEK-TROL - Tek-Clamp 1200A-100H Hand Held Ultrasonic Flow Meter

TEK-TROL - Tek-Clamp 1200A-100H Hand Held Ultrasonic Flow Meter

Tek-Clamp 1200A-100H has a built-in data logger capable of storing over 2000 data points (optional). The pair of transducers used are capable of measuring flow rates in pipes from ½" to 28" at temperatures of between 32 °F (0 °C) to 320 °F (160 °C).

TEK-TROL - Tek-Clamp 1200A-100EXP Wall Mount Ultrasonic Flow Meter

TEK-TROL - Tek-Clamp 1200A-100EXP Wall Mount Ultrasonic Flow Meter

The wall-mounted version of the 1200A Ultrasonic Flow Meter is designed to measure the fluid velocity of liquid in a full or closed pipe using three approaches: Clamp-on, flow-cell, and insertion for pipe diameters from 1/2 inch to 200 inches, with accuracy better than ±1% of reading.

TEK-TROL - Tek-Clamp 1200A-100M Low Cost DIN Mount Flow Meter

TEK-TROL - Tek-Clamp 1200A-100M Low Cost DIN Mount Flow Meter

The Tek-Clamp 1200A-100M modular ultrasonic flow meter can work without an LCD and Keypad module. So, the module can be used alone as a flow meter. Users can even integrate a number of the modules into a multi-channel flow meter that can measure different pipes—designed to provide high performance at a cheaper cost.