Tek-Trol

Tek-Trol provides pressure, level, flow, and temperature measurement in applications across all process industries – including oil and gas, power, food, Pharma, biofuels, chemical, water and wastewater, and more.

Why choose to use Tek-Trol? Tek-Trol sensors and instrumentation are excellent value for the money, and most products are manufactured in the USA. They have outstanding quality, performance, and accuracy with incredible pricing, typically much less than established big-name brands. With a part number configuration from another brand, contact SensorPros to send you a quotation for an equivalent product from Tek-Trol. You will be pleasantly surprised with the Tek-Trol pricing!

Product Categories

TEK-TROL - Tek-Flux 4100B Two-Wire TDR OEM Level Transmitter

TEK-TROL - Tek-Flux 4100B Two-Wire TDR OEM Level Transmitter

Measures distance, level, volume, and mass of liquids, solids. It is an affordable solution for applications that do not require a high level of accuracy and is an excellent alternative to traditional level controls such as RF Capacitance, conductive, and DP transmitters.

TEK-TROL - Tek-Wave 4300A Radar Level Transmitter

TEK-TROL - Tek-Wave 4300A Radar Level Transmitter

The Tek-Wave 4300A is anexplosion-proof, and it does not come in contact with the media. It can also be used to measure levels of corrosive, viscous, and abrasive materials without suffering any damage.

TEK-TROL - Tek-Wave 4300B Bluetooth Radar Level Transmitter

TEK-TROL - Tek-Wave 4300B Bluetooth Radar Level Transmitter

It is a perfect application for water treatment, storage tanks, open basins, pump/lift stations, sewer management rain overflow basins, and level monitoring.

TEK-TROL - Tek-Hydro 4500A-D Differential Pressure Level Transmitter

TEK-TROL - Tek-Hydro 4500A-D Differential Pressure Level Transmitter

Measures hydrostatic pressure head and converts into a liquid level. It is used to measure not only the liquid level but also other parameters such as the flow rate and density. This transmitter has a maximum pressure up to 1000PSI.

TEK-TROL Tek-Hydro 4500A-G Gauge Pressure Level Transmitter

TEK-TROL Tek-Hydro 4500A-G Gauge Pressure Level Transmitter

Used with a wide range of liquids, including corrosive, non-corrosive, and abrasive liquids and slurries in tanks of any size. It can handle broad temperature and pressure ranges under different process conditions. It also measures other parameters, such as the flow rate and density. Maximum pressure up to 8700PSI.

TEK-TROL - Tek-Sub 4800A PTFE Submersible Level Transmitter

TEK-TROL - Tek-Sub 4800A PTFE Submersible Level Transmitter

It is a rugged ceramic pressure sensor in PTFE housing with excellent corrosion resistance. Accuracy is +/-0.5% FS.

Operates on 12-36 VDC power, and available signal outputs are 4-20 mA, 0.5-4.5 VDC or RS-485.

TEK-TROL - Tek-Sub 4800B Submersible Level Transmitter

TEK-TROL - Tek-Sub 4800B Submersible Level Transmitter

The piezoresistive silicon sensor is enclosed in a 304 SS housing, a diameter of 1.06 inches (27 mm), and accuracy (+/-0.5% FS). It operates on 12-36 VDC power, and available signal outputs are 4-20 mA, 0.5-4.5 VDC, or RS-485.

TEK-TROL - Tek-Sub 4800C Borehole Submersible Level Transmitter

TEK-TROL - Tek-Sub 4800C Borehole Submersible Level Transmitter

With a piezoresistive silicon sensor in a 304 SS sensor body, it is only 19mm in diameter, ideal for narrow conduit installations. Accuracy is (+/-0.25% FS); signal output options are 4-20 mA, 0.5-4.5 VDC or RS-485.

TEK-TROL - Tek-Sub 4800D - Wastewater Submersible Level Transmitter

TEK-TROL - Tek-Sub 4800D - Wastewater Submersible Level Transmitter

Exclusively designed for slurry and wastewater applications, the Tek-Sub 4800D employs a clog-free design that measures the liquid level without being affected by debris.

TEK-TROL - Tek-Bar 3120A - Gauge/Absolute Pressure Transmitter

TEK-TROL - Tek-Bar 3120A - Gauge/Absolute Pressure Transmitter

Explosion-Proof (FM (Class I Div I), Pressure Ranges from -14.5 up to 217 psi gauge, and 0 to 8500 psi gauge, absolute ranges (optional), 100:1 turndown capability, and accuracy 0.075% of URL (0.04% optional). 4-20 mA HART®️ output standard (optional Modbus).

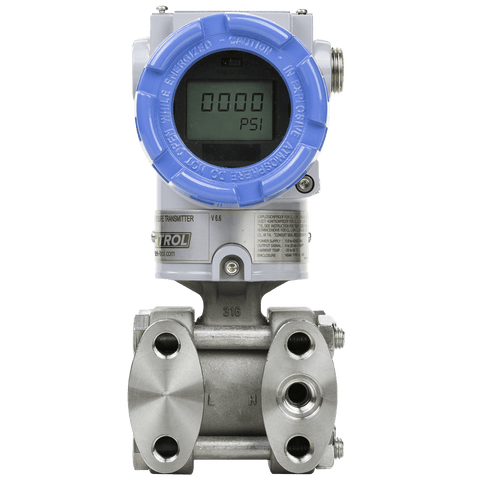

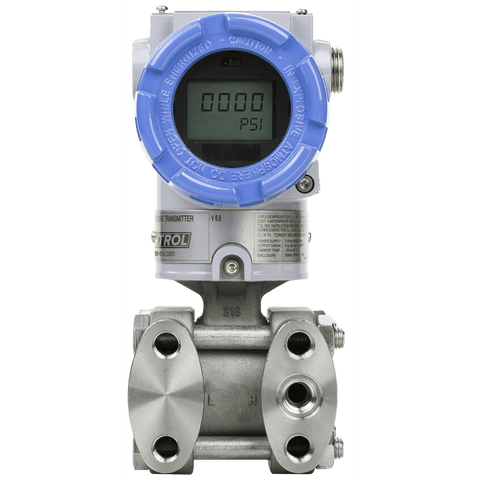

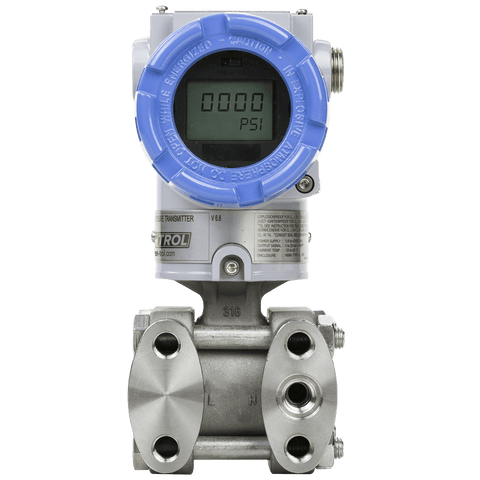

TEK-TROL - Tek-Bar 3110A Series - Differential Pressure Transmitter

TEK-TROL - Tek-Bar 3110A Series - Differential Pressure Transmitter

Explosion-Proof (FM (Class I Div I), Pressure Ranges from 0-6" WC up to 0-300 psi gauge, absolute or differential, 100:1 turndown capability, and accuracy 0.075% of URL (0.04% optional). 4-20 mA HART®️ output standard (optional Modbus).

TEK-TROL - Tek-Bar 3800XA Explosion-Proof Multivariable Transmitter

TEK-TROL - Tek-Bar 3800XA Explosion-Proof Multivariable Transmitter

Capable of measuring three separate process variables at the same time and provides the option of calculating the following values: 1) Mass flow for gases, steam, and liquids, 2) Standard volume flow for gases using dynamic compensation, 3) Heat flow for water and steam and 4) Drum water level and level measurement with density compensation of liquids.

TEK-TROL - Tek-Bar 3800E - Utilities/Non-Explosion Proof Multivariable Transmitter

TEK-TROL - Tek-Bar 3800E - Utilities/Non-Explosion Proof Multivariable Transmitter

Simultaneously measures multiple independent process variables. This Multivariable is suitable for a wide range of liquid, gas, and steam applications for measuring static and differential pressure, temperature, and mass flow.

TEK-TROL - Tek-Bar 3800XP Multivariable Transmitter/ Flow Computer

TEK-TROL - Tek-Bar 3800XP Multivariable Transmitter/ Flow Computer

Simultaneously measures multiple independent process variables. This Multivariable is suitable for a wide range of liquid, gas, and steam applications for measuring static and differential pressure, temperature, and mass flow.

TEK-TEMP 2100A SERIES EXPLOSION-PROOF TEMPERATURE TRANSMITTER

TEK-TEMP 2100A SERIES EXPLOSION-PROOF TEMPERATURE TRANSMITTER

Tek-Trol’s Explosion-Proof Temperature Transmitter is microprocessor-based and accepts temperature sensors such as Thermocouples, Resistance Temperature Detectors, and milliVolt and Resistance inputs.

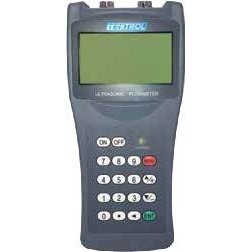

TEK-TROL - Tek-Clamp 1200A-100H Hand Held Ultrasonic Flow Meter

TEK-TROL - Tek-Clamp 1200A-100H Hand Held Ultrasonic Flow Meter

Tek-Clamp 1200A-100H has a built-in data logger capable of storing over 2000 data points (optional). The pair of transducers used are capable of measuring flow rates in pipes from ½" to 28" at temperatures of between 32 °F (0 °C) to 320 °F (160 °C).

TEK-TROL - Tek-Clamp 1200A-100EXP Wall Mount Ultrasonic Flow Meter

TEK-TROL - Tek-Clamp 1200A-100EXP Wall Mount Ultrasonic Flow Meter

The wall-mounted version of the 1200A Ultrasonic Flow Meter is designed to measure the fluid velocity of liquid in a full or closed pipe using three approaches: Clamp-on, flow-cell, and insertion for pipe diameters from 1/2 inch to 200 inches, with accuracy better than ±1% of reading.

TEK-TROL - Tek-Clamp 1200A-100M Low Cost DIN Mount Flow Meter

TEK-TROL - Tek-Clamp 1200A-100M Low Cost DIN Mount Flow Meter

The Tek-Clamp 1200A-100M modular ultrasonic flow meter can work without an LCD and Keypad module. So, the module can be used alone as a flow meter. Users can even integrate a number of the modules into a multi-channel flow meter that can measure different pipes—designed to provide high performance at a cheaper cost.

TEK-TROL - Tek-Bar 3110A-D-2-FM-1-SS-1-LCD - Differential Pressure Transmitter

TEK-TROL - Tek-Bar 3110A-D-2-FM-1-SS-1-LCD - Differential Pressure Transmitter

Product Series: Tek-Bar 3110A Series Differential Pressure Transmitter, Output: 4-20 mA HART®️ (2-wire),

Explosion-Proof (FM (Class I Div I), Pressure Range 0-6" WC, 100:1 turndown capability, accuracy 0.075% of URL

TEK-TROL - Tek-Bar 3110A-D-3-FM-1-SS-1-LCD - Differential Pressure Transmitter

TEK-TROL - Tek-Bar 3110A-D-3-FM-1-SS-1-LCD - Differential Pressure Transmitter

Product Series: Tek-Bar 3110A Series Differential Pressure Transmitter, Output: 4-20 mA HART®️ (2-wire), Explosion-Proof (FM (Class I Div I), Pressure Range 30" WC, 100:1 turndown capability, accuracy 0.075% of URL